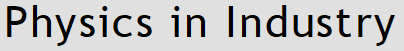

Heat and Flow

Heat and fluid flow – both play an essential role in innumerable different applications, each alone or in combination. Whether within a technological process, in heating or cooling of a production plant, in heat supply, water supply or process gas supply facilities or in air conditioning and exhaust air systems, whether in the heavy industry or in the sector of laboratory devices - in (almost) every industrial sector with a wide range of different applications. They are all based on the same physical principles and mechanisms: we are talking of mechanisms like fluid flow through pipes an apparatuses, heat and mass transport, heat conduction and convection heat transfer, heat radiation, heat and mass transfer, diffusion, and the interaction of these mechanisms under the particular boundary conditions.

You are experts for your technology and your processes, we are experts for the underlying physical mechanisms. We offer support in your development projects, in planning and engineering, in maintenance and in solving acute technical problems. We deliver concrete solutions and make seemingly complex processes comprehensible, computable and predictable.

We are offering support on quite different technical levels. Depending on your needs, we will deal either with a whole system or a subsystem or with some components, some apparatus or device, which will be investigated, analyzed, optimized. We will consider questions concerning layout and functioning of a device or put our focus on the technological processes which take place within.

Designing and optimizing systems

- Procedural layout and basic engineering

- Design of heating and cooling systems

- Layout of piping systems

- Concepts for energy efficiency and carbon dioxide reduction

- Flow mesurements in supply and exhaust air systems

- Measurements of emissions

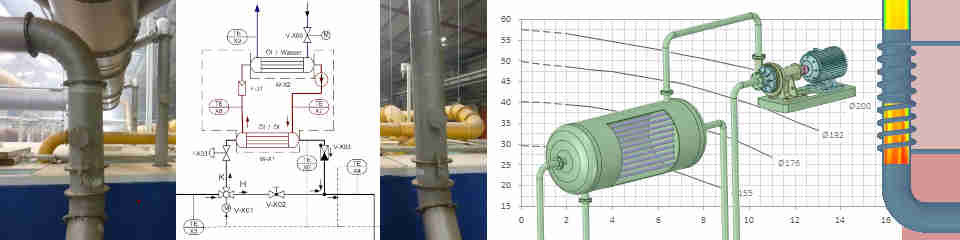

Functionally optimized designing of components

- Heating up a tank, a reaction vessel or some material quickly, is not a big deal. In case of electrical heating, it's just a question of the supplied electrical power. However, quick heating or cooling becomes a challenge, if, during the process, temperature distribution should stay as uniform as possible. How must heating coils in an vessel, how must resistance tracks on a plate be designed or distributed, so that at a certain power supply temperature rises uniformly? How a radiation heating has to be designed? What degree of temperature constancy can be realized?

- How can lost heat from electrical devices and control cabinets, how can reaction heat from some chemical process be removed effectively? How can pipes, conveying hot flue gases, be effectively cooled to avoid local overheating? How must cooling fins be designed and distributed, in order to dissipate heat most effectively?

These are just a few examples to demonstrate, how deeply construction details and thermal characteristics are interconnected. The laws of thermodynamics and fluid dynamics are all well-known and every possible individual application can be computed and optimized.

Computation and simulation of technological processes

In many production processes, heating and cooling, possibly comprising phase transitions or chemical reactions, play an essential role, be it in a cycle operation, be it in a continuous process. Starting from the underlying physical mechanisms, and applying them on the particular plant and process design, we will compute process-relevant physical state variables like temperature, pressure, moisture, concentrations, etc., and thus simulate the process. We offer:

- computation of process-relevant physical state variables,

- development of software tools for computation and simulation of processes.